Echoes

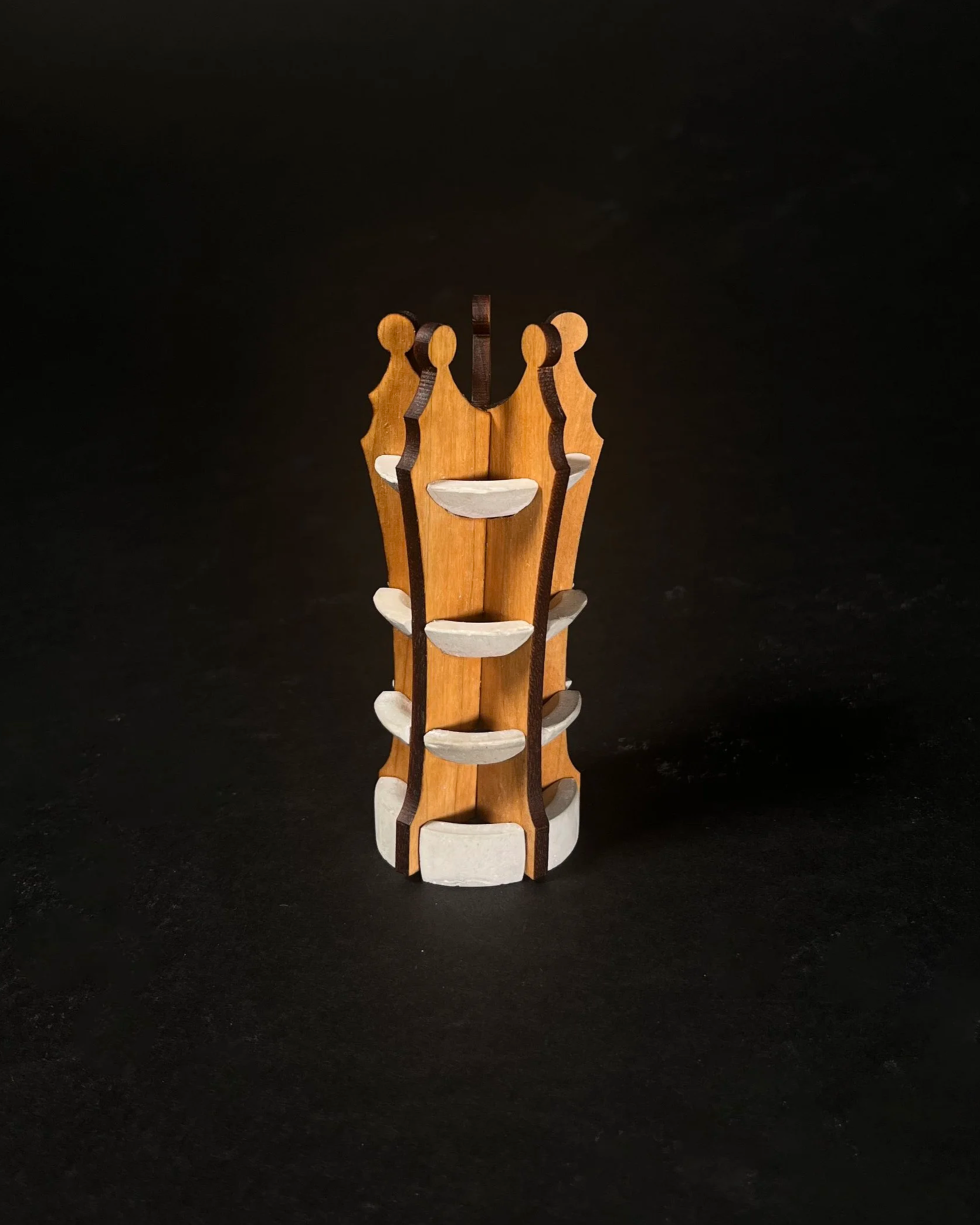

Project Intent: Redesign the classic chess set emphasizing a family of form while maintaining easily identifiable pieces. Utilize a common, cast portion in all pieces.

Project Duration: 5 Weeks

Setting Goals

Radial footprint, traditional profiles, interlocking components

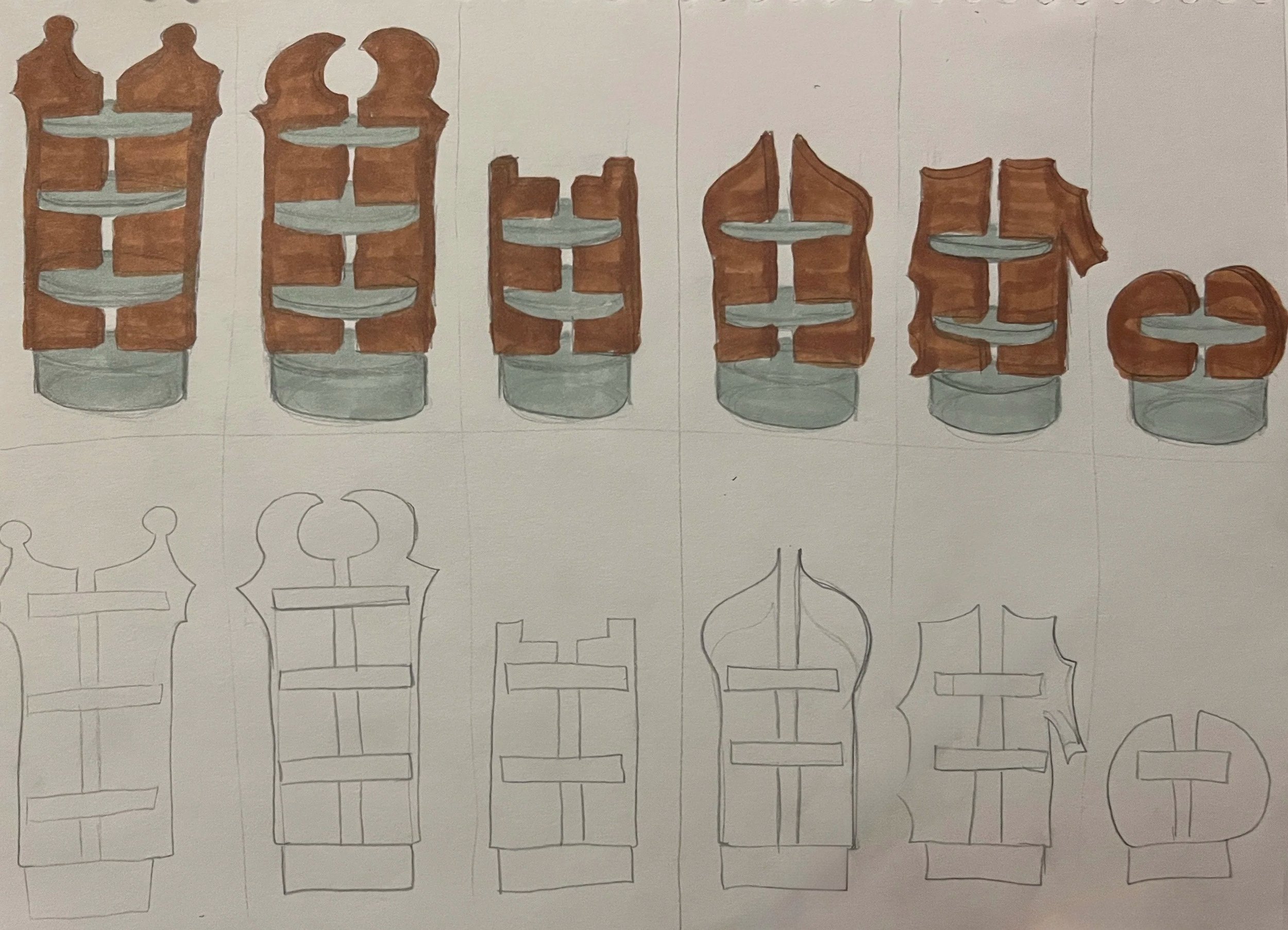

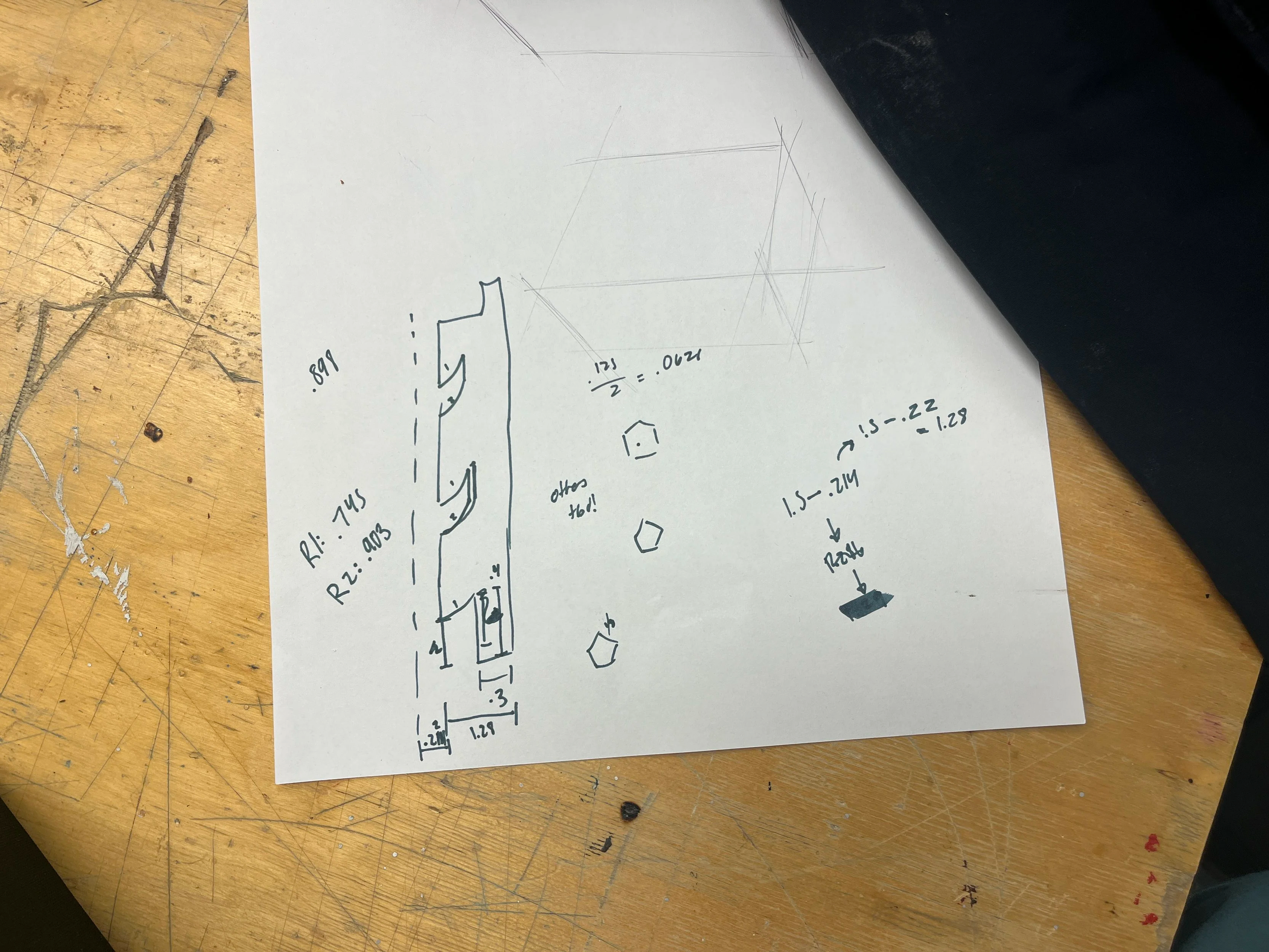

Sketch Ideation

Exploring possible form families, playing with profiles and identifying features of each piece

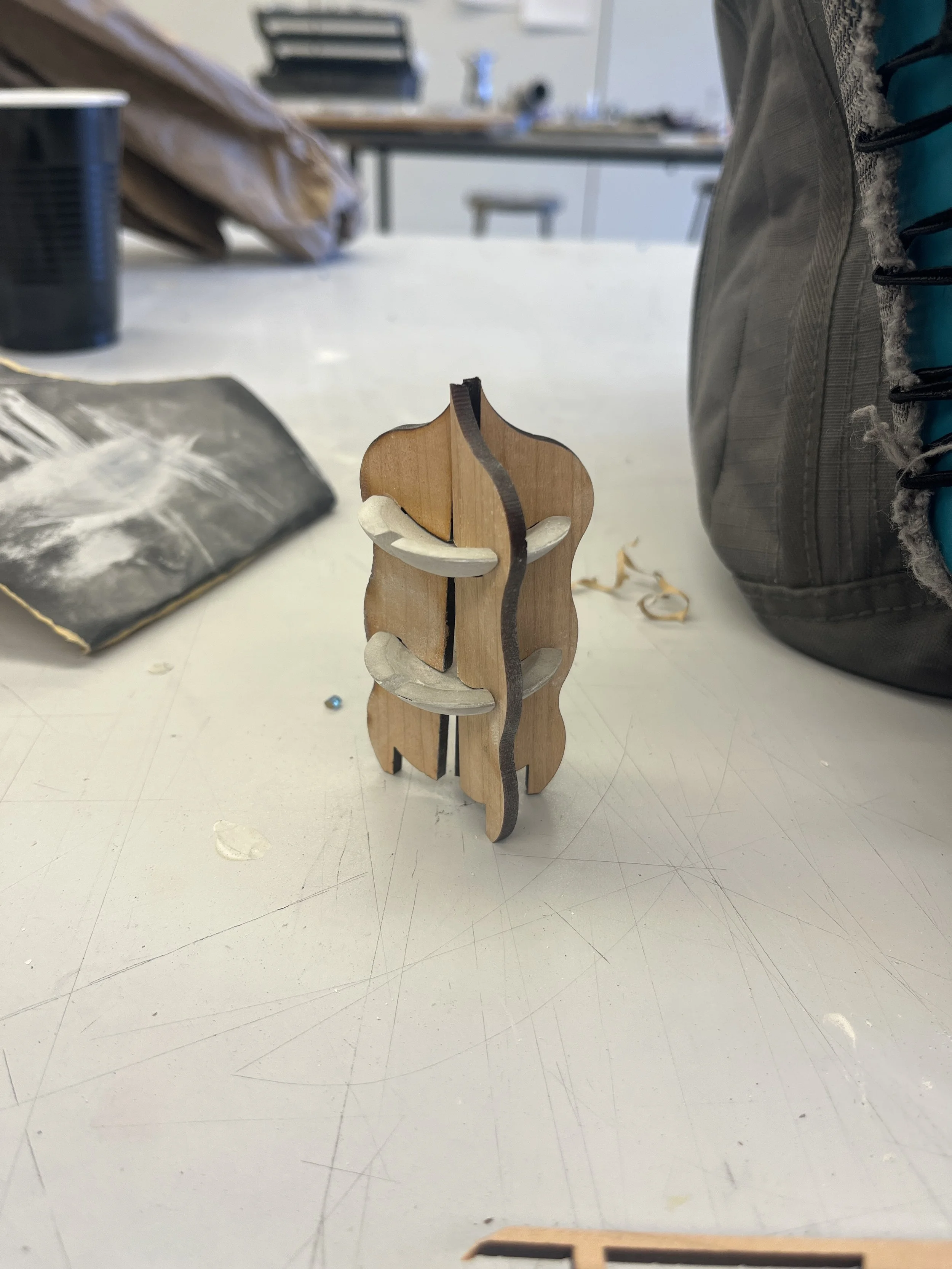

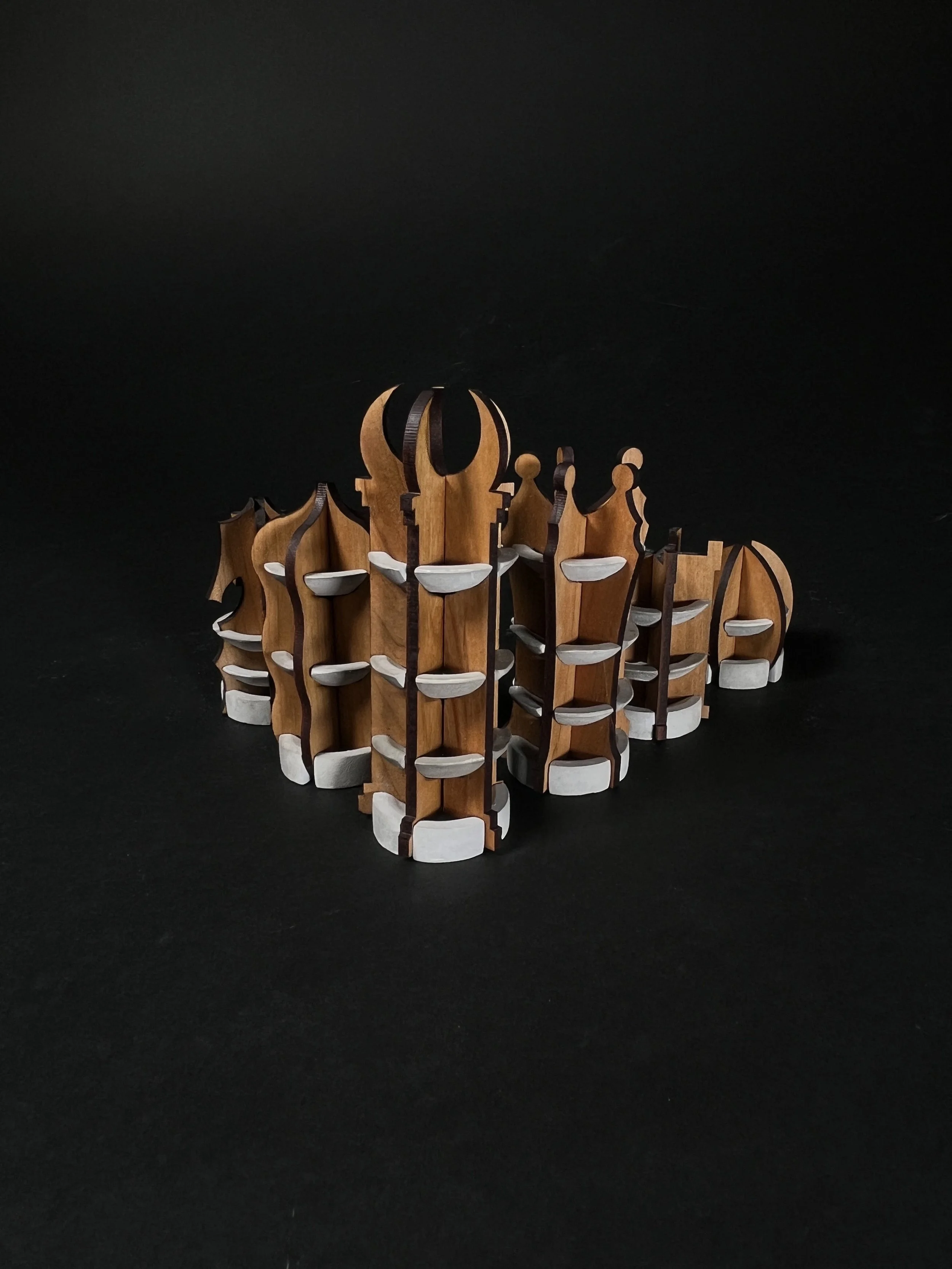

Moving Forward into tactile models

Drawn to interaction between contrasting materials, sturdy bases, and echoing effect of layers vertically, laterally, and radially

Quick Rendering Ideation

Practicing Manufacturing Methods & Testing Human Interaction

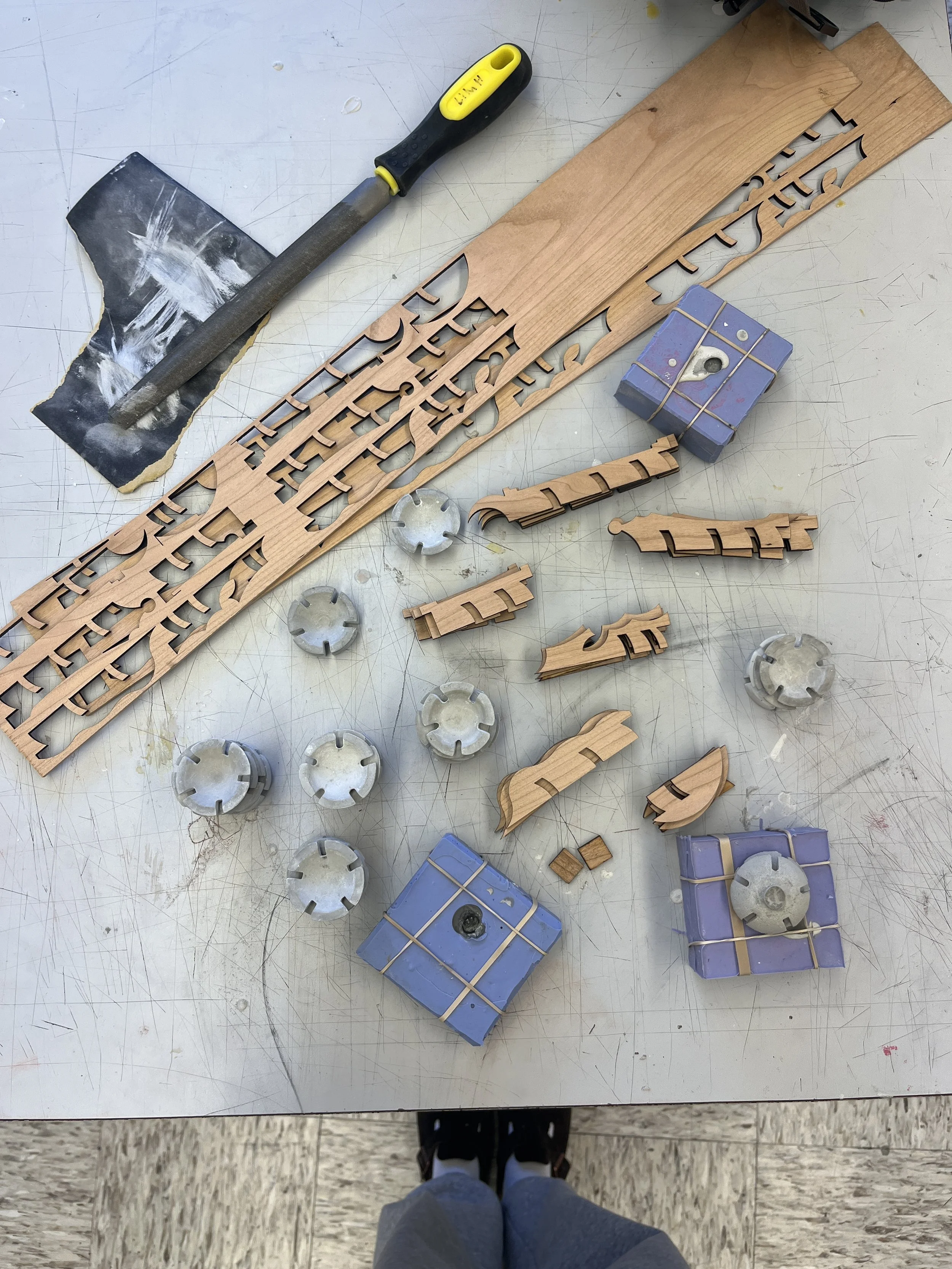

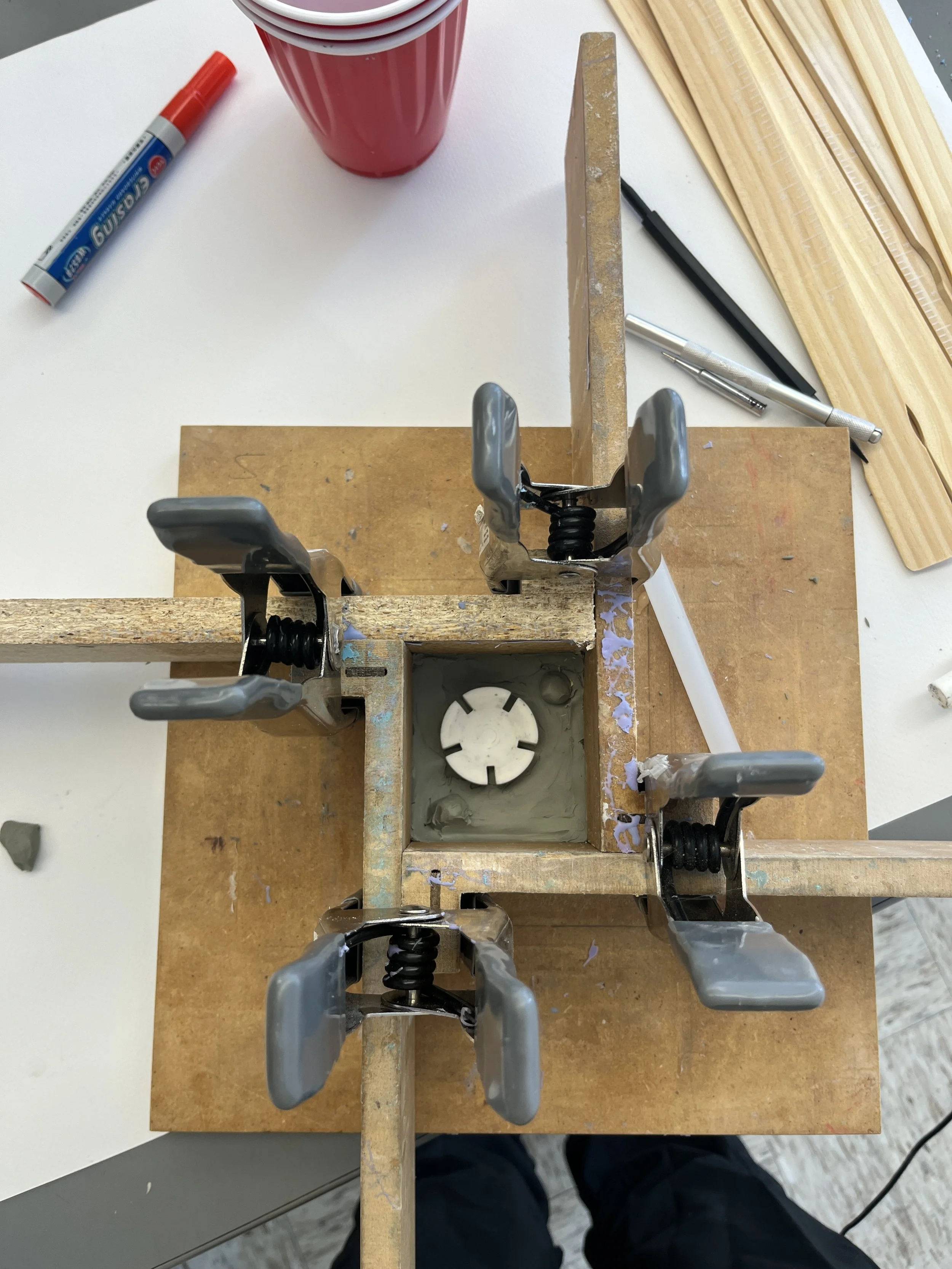

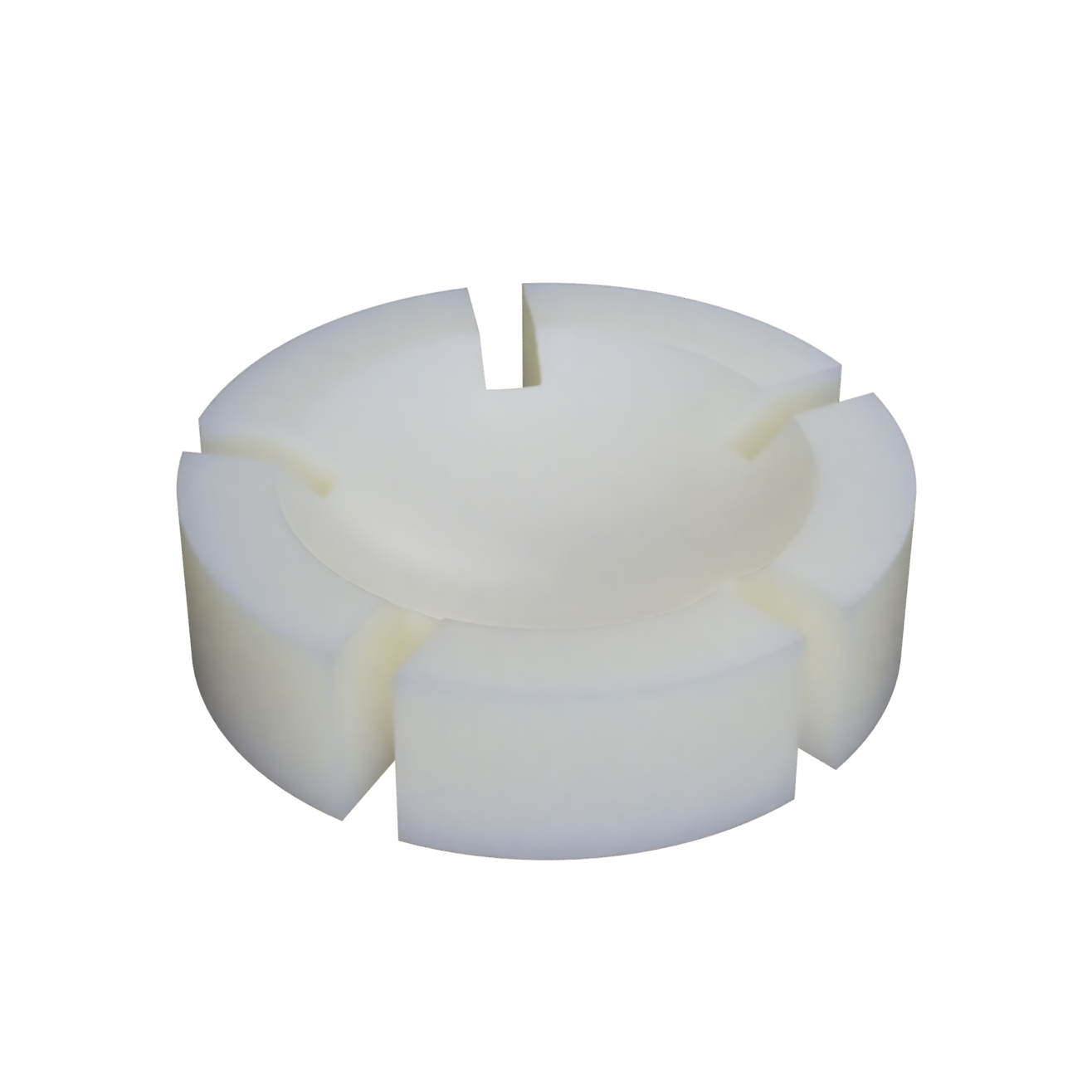

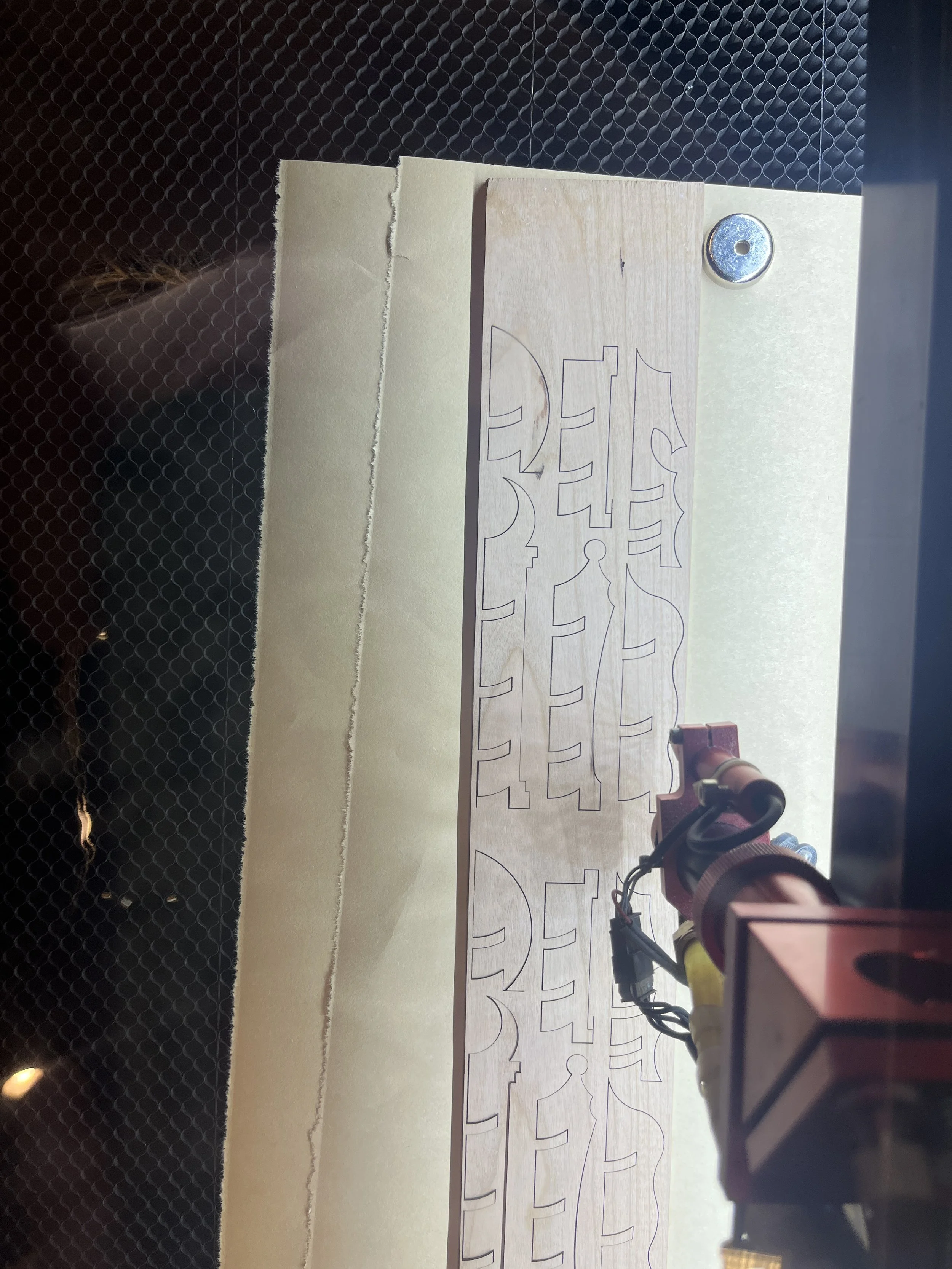

Final Model Production

Casting bases and floating disks of Rockite in rubber molds, sanding pour spouts, filling in cosmetic inconsistencies; Laser cutting wooden profiles; assembling with tension fit.

Design Considerations

Use cement for cast pieces to have a weighted feel to pieces and a strong structural appearance.

Vary the number of disks in pieces to show hierarchy.

Convert flat disks to a bowl-like shape to take full advantage of casting process and to emphasize echoing of pieces as they layer.

Echo wooden profiles five times around to utilize radial symmetry while maintaining cleanliness and interest through economy.

Contrast “black” and “white” sides by using cherry for the light side and walnut for the dark.

Utilizing rubber molds to cast Rockite concrete and laser cutter to define wooden profiles

Production Methods

3D print base and disk pieces to create rubber mold to ensure uniformity and precision.

Laser cut wooden profiles to ensure precision and manufacturability and to add a darkened edge for contrast.

Sand down pour spout in cement pieces from molding process.

Interlock notches in both wood and rockite to hold pieces together.